The RSP Reinforced Spiral HDPE pipe, manufactured using the advanced extrusion winding process, is the economical solution for light-duty drainage culvert applications for low-density areas such as plantations and rural areas.

Compared against conventional HDPE open-profiled spiral pipes in the market, RSP has higher ring and bending stiffnesses. They are designed to meet DIN 16961 Part 1 and 2; as well as ASTM F894 and AASHTO M294 standards for polyethylene corrugated pipes for drainage.

The allowable burial depths of the RSP pipes depend on backfill material, compaction and imposed loads for the application of the pipe.

Applications

> Culverts for plantations and rural roads

> Drainage pipes

> Irrigation pipes

Product Features

> FLEXIBLE – Able to bend and conform to soil conditions without fracture failure

> CORROSION RESISTANT – HDPE requires no protective painting maintenance against rusting

> UV RESISTANT – The HDPE material for RSP pipes contains carbon black additives which are excellent UV retardants for outdoor exposure

> LIGHTWEIGHT – HDPE products are inherently light and eases transportation, handling and installation

> CHEMICAL RESISTANT – HDPE, being an inert material, can resist the extremes of pH in soil, sewage and wastewater without degrading

> ABRASION RESISTANT – HDPE resists abrasion better than conventional material like concrete and steel which can pit and rust. As a result, FLOLINE 3-W pipes can ensure good, long-term flow characteristics

> REDUCED RISK OF LEAKAGE – RSP pipes are available in long lengths and require fewer joints

> SIRIM CERTIFIED & SPAN APPROVED – RSP Reinforced Spiral Pipes are certified to DIN 16961 Part 1 & 2 by SIRIM with Product Certification Listing by SPAN (Suruhanjaya Perkhidmatan Air Negara)

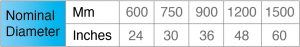

Size Range